-

Take a digital picture of the part

BEFORE it is removed from the playfield.

-

Once the piece is removed, write

down what was removed, how many and what kind of

screws/bolts/nuts/washers were used. If a connector is

diconnected to remove the piece, label BOTH sides of the connector

with a letter and make a note of the letter used.

-

Place the items removed into a

Ziploc bag and number the bag with a Sharpie to correspond with

the number that was written down in the previous step. If

the piece is too big (like a ramp), place it in a large plastic

storage box and place it's screws/bolts into a bag.

You should end up with lots of bags

that look like this ...

... and a parts box that looks like

this. I store all of the plastic bags inside a cardboard

box. The entire contents of the playfield is stored

neatly in one container, with the wiring harness to be removed

later. This is great if the playfield is being sent off to get

clearcoated as you won't have to worry about losing parts while it's

gone.

Once the top of the playfield has

been stripped, the wiring harness from the playfield into the backbox

must be disconnected. There are two looms of wire that go into

the backbox - one from the playfield and one from the cabinet.

Identify which is from the playfield. As you remove the

connectors from the circuit boards, use a sharpie and write the number

of the board connector (like 101,203, 906, etc) on the side of the

wire connector.

After the entire loom has been

disconnected from the backbox, remove the playfield from the cabinet

and place it face down on a packing blanket or towels. Remove

any parts NOT connected to the wiring harness (playfield slides),

continuing to use the same list procedure from the top of the

playfield.

Everything should now be removed

expect for the wiring harness. There will be three type of screws

you will remove -

-

Machine screws, which are used

for larger assemblies.

-

Silver hex head wood screws,

used on a majority of the parts.

-

Gold hex head wood screws, used

mostly on lamp sockets.

Note that the gold screws are SHORTER

than the silver ones. Do NOT use the wrong length screw when

reassembling the harness or the screw WILL poke through the top of the

playfield. If you are unsure of what screws will go where, mark

EVERY screw hole as you remove the screw using a different colored

marker for each type.

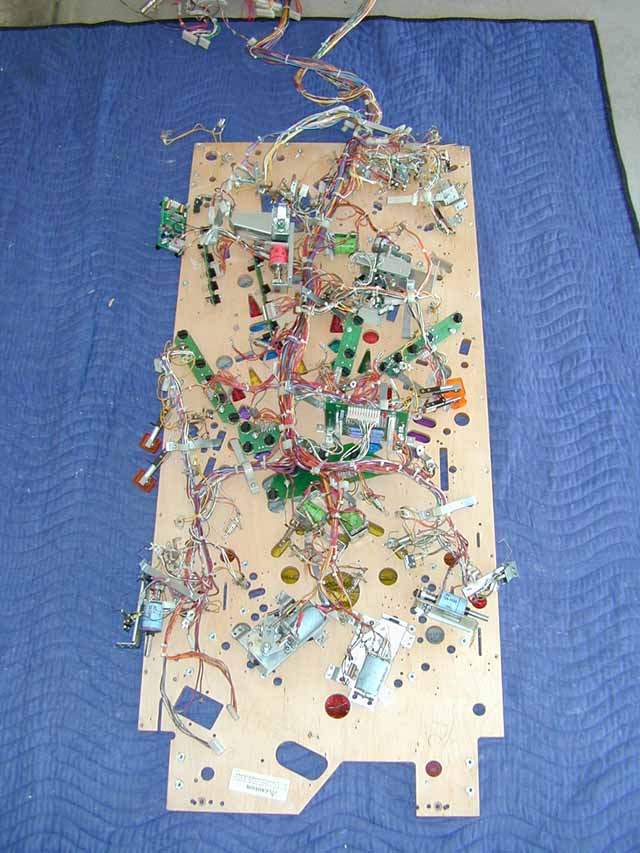

With all the screws removed, the

harness should still be sitting loose on the back of the playfield.

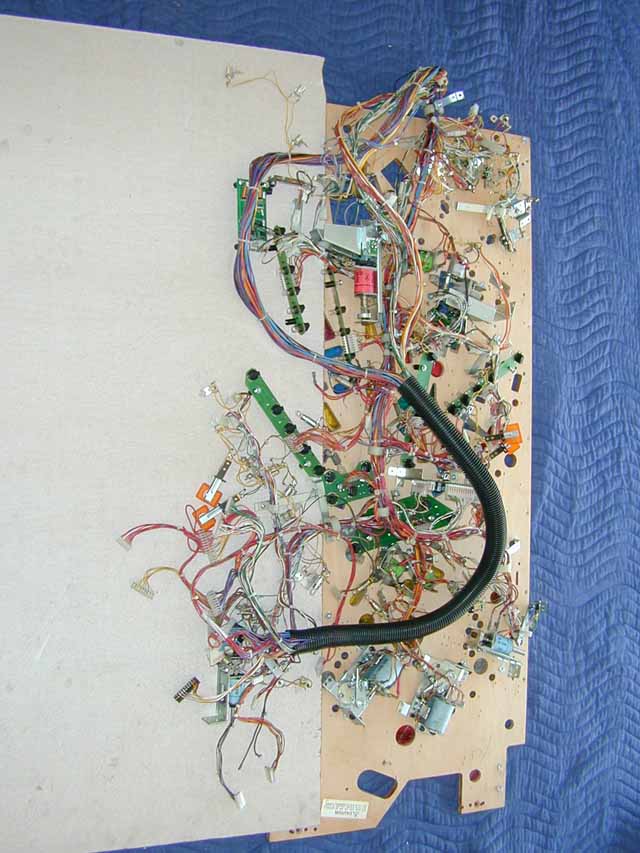

Using a thin board (or thick

cardboard) cut slightly larger than the playfield itself, begin

sliding it under the harness, lifting up parts and placing them onto

the board. Don't worry about keeping everything in its exact

place. It will be fairly obvious where everything goes when you

put the harness back onto the playfield.

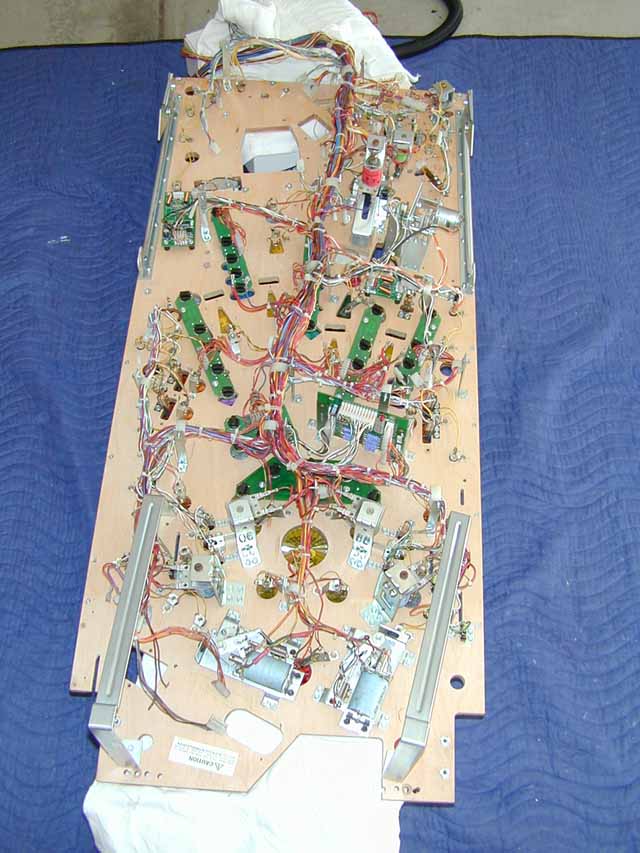

When you are done, the harness should

be completely on the board. You now only need to remove the few

items left on the playfield, like pop bumper studs. At this

point, the playfield may either be swapped with a new one or the

existing one may be touched up and/or clearcoated.

While the playfield is being

swapped/repaired, this is a good time to do things like flipper

rebuilds and target/switch replacement. Also, replace all the

bulbs at this time. It's much easier to work on the harness when

it in this orientation instead of back in the cabinet. You'll

have a few week if you send the playfield off to be clearcoated, so

use the time wisely.

After the playfield has been

repaired/swapped, reverse the process above. Slide the harness

off the board and back onto the playfield. Screw everything back

onto the playfield, ensuring you are using the correct LENGTH screw

for the piece you are installing. It will start taking shape as

you near the end of this step.

When installing the pop bumper studs

back into the playfield, use an old leg bolt on the head of the stud

as you hammer it back into the playfield. You'll be less likely

to damage the playfield with an errant hammer hit. And if you

clearcoated the playfield, the last thing you'd want to do is smack it

with a hammer.

After the playfield is placed back

into the cabinet for re-assembly, just go back up the list you made

during disassembly. It should go together fairly easily as

everything is numbered. Refer to the digital pictures you took

for each step should you have a question on how a part is oriented.